Ancient Solar Stone cutting Techniques

Fracturing stones with an intense beam of light is easy. In the first tests carried out with sun dishes, most stones shattered almost instantly. It was only after controlling the way the heat was delivered that stones ceased to split on contact with the beam. This allowed a number of more subtle effects to be realized.

Amongst these techniques, there is gem annealing, stone glazing, ceramic creation, food cooking, metal vaporizing, metal welding, metal cutting and many more. These procedures were developed originally over centuries of dish use. As a scientist with clues from the archaeological record and modern texts, they were all developed over the course of a year or two.

These techniques clearly point up the ladder of sun dish skills. Possibly at the top is the ability to cut and write in stone with light. Whilst simple roman numerals have already been written in stone and stones have been fractured, there are finer methods that use control systems.

These controls are nothing more sophisticated than paints or charcoal to protect or help heat particular areas. Light guards to guarantee the direction of the beam. Finally, there are templates that allow patterns to be made without error.

These are currently being developed and tested as time permits. The inspiration comes from the ancient Talmudic texts. They describe both stone cutting and writing in gems with the Shamir. The extract below from The Ancient Solar Premise relates the content from the various sources.

Current Research

The techniques currently being tested follow two streams. Firstly, gemstones are being coated with a mask of charcoal, paint or ink and the responses of various gems are being tested. Whilst ceramic paints have already been melted onto stone and pottery, this is an alternative way to write in stone. The body of the gem or stone will react differently in places where it is painted.

Gems have already been changed completely or partially with a beam of light. New fundamentals being established are as follows. Will the paint protect the gem color and allow the rest to change. This will lead to an original color under the paint and a faded color around the paint. Alternatively, will the reverse happen? Will the dark paint absorb more light and heat up the gem beneath the paint causing it to change color?

Testing requires the correct paint, ink, charcoal, light intensity, dish size, stone selection, time of exposure, ambient weather and patience.

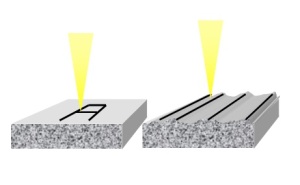

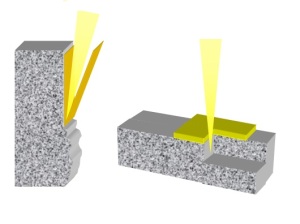

The second technique involves using light guards to protect areas of the stone and expose other parts. When water is poured onto the heated section of stone, small chunks can presumably be fractured away quite quickly. This is a more sophisticated version of the fracturing already established. It also allows some degree of control over the beam. In principle, very small dishes can be used to deliver very fine work.

There is no doubt the stones will fracture, but there are additional things to discover. New fundamentals being established are as follows. How fast is the process with dishes, how small can the sun dish be, how accurate can the cuts be made, exposure times, water-cooling and which metals will be used?

In the past gold plates seem to have been used. Budgets preclude this option, but modern shiny metals should suffice. The reflective properties prevent too much light being absorbed and the metal will not melt. This process is already being used in laser systems that etch onto stones. Small movable metal plates move whilst the laser remains fixed. As they move, the tip of the beam is directed to a different spot. It is a very successful technique.

Testing requires the right ambient weather, exposure times, rock selection, light guard spacing, template alignment, template distances and of course patience.

Both techniques are outlined in the Talmudic texts summarized below. The techniques are only minor extensions to work already carried out with tools actually found in the archaeological record. This places a device in the hands of the ancient stonemason that:

Extract from The Ancient Solar Premise

The Shamir

Cutting stone might be thought of as rather an extreme application of solar techniques. There would surely be some text support for such an amazing method. Apart from the references from Peru, there are others that have a more surreal quality. The Shamir is a fabled device that is related from both Arab legend and Jewish texts. Its provenance can be traced back to the Exilic Jews, but there is much between it and fact. This is dealt with more fully in the book A Brief History of the Sun Sects. However, a brief summary is instructive.

There are two accounts of the Shamir being used in ways that have a certain resonance with the techniques in this text. Outside of the ideas expressed and tested here, no others even come close to matching this myth with real tools. The Shamir was used to write in stone by Moses during the exilic years and to build the Temple of Solomon.

In the oldest part of the myth, the Shamir was used in preparing stones for the ritual garb of the Tabernacle. In Exodus, it says that the precious stones for the Urim and Tummim were to be engraved with the names of the twelve tribes “like the engravings of a signet”. No ordinary tool was to be used in this sacred work making the cuts in the stones. Scripture required that the stones remain “in their fullness.”

Bezalel and his workers first wrote the names in ink on each of the gemstones (ruby, topaz, smaragd, garnet, sapphire, emerald, zircon, agate, amethyst, beryl, jasper, onyx). Then the shamir performed its work. This etched the names with such skill that not one atom of stone was lost. In some interpretations, the inked stones were shown the Shamir or exposed to its action.

In the more recent part of the tale, the Shamir neatly solves some problems caused by constraints put on the temple building process. The brief mention comes from Kings and notes that David was attempting to build the Temple of Solomon in Jerusalem. The main limit was that no metal tools were to be used: “For the house, while it was in the building, was built of stone made ready at the quarry; and there was neither hammer nor axe nor any tool of iron heard in the house while it was being built.”

The biblical injunction read: “….if you make me an altar of stone, you shall not build it of hewn stones; for if you lift up your tool upon it, you have polluted it.” Iron tools were linked to the sword, which was a weapon of war and death. In contrast, the altar and temple were the symbols of peace and life. Solomon wanted the altar and all the stonework in the temple to be made ready at the quarry without using any metal tool or instrument.

This might be a big constraint, but there also seems to have been neighbor trouble. They were complaining about the noise of the temple construction. This seems unlikely since a ruler would not have to listen to the locals. Whether true or not, the Shamir provided an answer that betrayed another of its properties. At the end of the Arab version, the king summons the Jinns from the Samur Mountains to his aid. They seem to have had many Shamir stones (samurs), which could shape and polish the stone blocks ‘noiselessly’.

These actions have a certain parallel to the sun dish techniques noted. The gemstone changes of colors are related along with results where only parts of the stone were etched. Seven of the gems mentioned were tested and changed quite easily with a small dish. Likewise, the use of paints, inks or charcoal to change parts of stones is outlined. It also strikes a chord with the ink and template methods used to cut granites and other stones. Most of all it is the ability to cut stones silently. What other method of stone cutting is there that can cut stone without noise? This is definitely not the chisel, sander, boulder, power saw or any other tool but light.

Whilst the actions of the tool have a bearing, the physical properties also add some clues. The tool was said to be a worm, about the size of a barley grain and able to cut through anything.

The ‘worm’ description seems to derive from the fact that the tool is not a mineral but living. This defies even the best minds, unless it is simply the point of light at the tip being described. This intense spot of light is not living or dead, but a dynamic tube of intense power. How else would they have described it?

This point of light can be made the size of a barley grain and it will shatter anything, even hard, durable stones. The rocks were said to split of their own accord at the markings, as a fig opens. Indeed stones do split on there own when exposed to the beam as tests have shown. It is suspected that the barley connection arises from the storage box details.

From the Greek works on Solomon, the Shamir is described as a green stone. A dish made of brass or bronze or any non-gold alloy would green with age. The color is seen on many metal museum pieces. Whether this is correct or not, it is the best of a poor set of answers. There are no green stones able to cut through granites and other hard rocks.

Lastly, there is the storage of this fabled object to deal with. The tool was looked after by the Hoopoe-bird. He kept it in a lead box, wrapped in a cloth amongst some barley grains. Only lead could resist the action of the device. This would be a surprise if it were active because lead is easily melted with a dish. The contradiction in being the size of barley grain, but wrapped in a cloth amongst others is clear. For a start, it could get lost in with all the others if it fell out of the cloth. It would also be strange to wrap up something the size of a grain of barley.

If it were a dish, it would be wise to keep it within a sealed box. This prevents the dish becoming dangerous in the presence of the sun. Barley is a quite effective at keeping moisture at bay within a sealed box. This would be wise if the device was made of an alloy since it would degrade quite quickly. The cloth would protect a dish from being bent out of shape in the event the box was dropped.

On balance, it is hard to separate fact from myth as with most history. Some have taken these notions and made radioactive theories, the priests have invoked the powers of gods. As far as the author is aware, the solar tools here are the only ones able to deliver all of the facilities afforded to this device. There is much more of this type of reasoning in A Brief History of the Sun Sects. The tool is put into context alongside the Tabernacle and the needs of the people of Moses. For the moment, this tale is just a sidebar on an eminently useful device that still has a few more things to deliver

These techniques clearly point up the ladder of sun dish skills. Possibly at the top is the ability to cut and write in stone with light. Whilst simple roman numerals have already been written in stone and stones have been fractured, there are finer methods that use control systems.

These controls are nothing more sophisticated than paints or charcoal to protect or help heat particular areas. Light guards to guarantee the direction of the beam. Finally, there are templates that allow patterns to be made without error.

These are currently being developed and tested as time permits. The inspiration comes from the ancient Talmudic texts. They describe both stone cutting and writing in gems with the Shamir. The extract below from The Ancient Solar Premise relates the content from the various sources.

Current Research

The techniques currently being tested follow two streams. Firstly, gemstones are being coated with a mask of charcoal, paint or ink and the responses of various gems are being tested. Whilst ceramic paints have already been melted onto stone and pottery, this is an alternative way to write in stone. The body of the gem or stone will react differently in places where it is painted.

Gems have already been changed completely or partially with a beam of light. New fundamentals being established are as follows. Will the paint protect the gem color and allow the rest to change. This will lead to an original color under the paint and a faded color around the paint. Alternatively, will the reverse happen? Will the dark paint absorb more light and heat up the gem beneath the paint causing it to change color?

Testing requires the correct paint, ink, charcoal, light intensity, dish size, stone selection, time of exposure, ambient weather and patience.

The second technique involves using light guards to protect areas of the stone and expose other parts. When water is poured onto the heated section of stone, small chunks can presumably be fractured away quite quickly. This is a more sophisticated version of the fracturing already established. It also allows some degree of control over the beam. In principle, very small dishes can be used to deliver very fine work.

There is no doubt the stones will fracture, but there are additional things to discover. New fundamentals being established are as follows. How fast is the process with dishes, how small can the sun dish be, how accurate can the cuts be made, exposure times, water-cooling and which metals will be used?

In the past gold plates seem to have been used. Budgets preclude this option, but modern shiny metals should suffice. The reflective properties prevent too much light being absorbed and the metal will not melt. This process is already being used in laser systems that etch onto stones. Small movable metal plates move whilst the laser remains fixed. As they move, the tip of the beam is directed to a different spot. It is a very successful technique.

Testing requires the right ambient weather, exposure times, rock selection, light guard spacing, template alignment, template distances and of course patience.

Both techniques are outlined in the Talmudic texts summarized below. The techniques are only minor extensions to work already carried out with tools actually found in the archaeological record. This places a device in the hands of the ancient stonemason that:

- Requires no energy or effort apart from the sun

- Requires little if any maintenance

- Works noiselessly as mentioned below

- Cuts through virtually any stone hard or soft

- Delivers the requisite accuracy to inscribe in small gems

- Produces the fine stonework identified in antiquity

- Delivers the huge cuts noted in ancient rocks with large dishes

Extract from The Ancient Solar Premise

The Shamir

Cutting stone might be thought of as rather an extreme application of solar techniques. There would surely be some text support for such an amazing method. Apart from the references from Peru, there are others that have a more surreal quality. The Shamir is a fabled device that is related from both Arab legend and Jewish texts. Its provenance can be traced back to the Exilic Jews, but there is much between it and fact. This is dealt with more fully in the book A Brief History of the Sun Sects. However, a brief summary is instructive.

There are two accounts of the Shamir being used in ways that have a certain resonance with the techniques in this text. Outside of the ideas expressed and tested here, no others even come close to matching this myth with real tools. The Shamir was used to write in stone by Moses during the exilic years and to build the Temple of Solomon.

In the oldest part of the myth, the Shamir was used in preparing stones for the ritual garb of the Tabernacle. In Exodus, it says that the precious stones for the Urim and Tummim were to be engraved with the names of the twelve tribes “like the engravings of a signet”. No ordinary tool was to be used in this sacred work making the cuts in the stones. Scripture required that the stones remain “in their fullness.”

Bezalel and his workers first wrote the names in ink on each of the gemstones (ruby, topaz, smaragd, garnet, sapphire, emerald, zircon, agate, amethyst, beryl, jasper, onyx). Then the shamir performed its work. This etched the names with such skill that not one atom of stone was lost. In some interpretations, the inked stones were shown the Shamir or exposed to its action.

In the more recent part of the tale, the Shamir neatly solves some problems caused by constraints put on the temple building process. The brief mention comes from Kings and notes that David was attempting to build the Temple of Solomon in Jerusalem. The main limit was that no metal tools were to be used: “For the house, while it was in the building, was built of stone made ready at the quarry; and there was neither hammer nor axe nor any tool of iron heard in the house while it was being built.”

The biblical injunction read: “….if you make me an altar of stone, you shall not build it of hewn stones; for if you lift up your tool upon it, you have polluted it.” Iron tools were linked to the sword, which was a weapon of war and death. In contrast, the altar and temple were the symbols of peace and life. Solomon wanted the altar and all the stonework in the temple to be made ready at the quarry without using any metal tool or instrument.

This might be a big constraint, but there also seems to have been neighbor trouble. They were complaining about the noise of the temple construction. This seems unlikely since a ruler would not have to listen to the locals. Whether true or not, the Shamir provided an answer that betrayed another of its properties. At the end of the Arab version, the king summons the Jinns from the Samur Mountains to his aid. They seem to have had many Shamir stones (samurs), which could shape and polish the stone blocks ‘noiselessly’.

These actions have a certain parallel to the sun dish techniques noted. The gemstone changes of colors are related along with results where only parts of the stone were etched. Seven of the gems mentioned were tested and changed quite easily with a small dish. Likewise, the use of paints, inks or charcoal to change parts of stones is outlined. It also strikes a chord with the ink and template methods used to cut granites and other stones. Most of all it is the ability to cut stones silently. What other method of stone cutting is there that can cut stone without noise? This is definitely not the chisel, sander, boulder, power saw or any other tool but light.

Whilst the actions of the tool have a bearing, the physical properties also add some clues. The tool was said to be a worm, about the size of a barley grain and able to cut through anything.

The ‘worm’ description seems to derive from the fact that the tool is not a mineral but living. This defies even the best minds, unless it is simply the point of light at the tip being described. This intense spot of light is not living or dead, but a dynamic tube of intense power. How else would they have described it?

This point of light can be made the size of a barley grain and it will shatter anything, even hard, durable stones. The rocks were said to split of their own accord at the markings, as a fig opens. Indeed stones do split on there own when exposed to the beam as tests have shown. It is suspected that the barley connection arises from the storage box details.

From the Greek works on Solomon, the Shamir is described as a green stone. A dish made of brass or bronze or any non-gold alloy would green with age. The color is seen on many metal museum pieces. Whether this is correct or not, it is the best of a poor set of answers. There are no green stones able to cut through granites and other hard rocks.

Lastly, there is the storage of this fabled object to deal with. The tool was looked after by the Hoopoe-bird. He kept it in a lead box, wrapped in a cloth amongst some barley grains. Only lead could resist the action of the device. This would be a surprise if it were active because lead is easily melted with a dish. The contradiction in being the size of barley grain, but wrapped in a cloth amongst others is clear. For a start, it could get lost in with all the others if it fell out of the cloth. It would also be strange to wrap up something the size of a grain of barley.

If it were a dish, it would be wise to keep it within a sealed box. This prevents the dish becoming dangerous in the presence of the sun. Barley is a quite effective at keeping moisture at bay within a sealed box. This would be wise if the device was made of an alloy since it would degrade quite quickly. The cloth would protect a dish from being bent out of shape in the event the box was dropped.

On balance, it is hard to separate fact from myth as with most history. Some have taken these notions and made radioactive theories, the priests have invoked the powers of gods. As far as the author is aware, the solar tools here are the only ones able to deliver all of the facilities afforded to this device. There is much more of this type of reasoning in A Brief History of the Sun Sects. The tool is put into context alongside the Tabernacle and the needs of the people of Moses. For the moment, this tale is just a sidebar on an eminently useful device that still has a few more things to deliver

Wow. Great post. Is this stone cutting process something that we can recreate today without any extra technology? It's very impressive information.

ReplyDeleteYes this tech can be recreated today. I have successfully tested the vast majority of the techniques. The photos of the work is on my FB albums and Wordpress page.

DeleteThat sounds down right cool. Would stone cutting be easier with this? Or would it take more time and money?

ReplyDeleteIt is very cool Jenny. I have tested the speed and practicalities and it can not compete with an industrial power saw with diamond blade like those used in modern quarries. It is tough to argue the case against the laser cutters that deliver photos into granite. It is the awkwardness, reliance on sunlight and lower control that probably prevents these being used in developed countries.

DeleteOn the other hand a dude with a remote workshop and little money might gain from a device that uses zero energy, never needs spare parts and can be made for a few dollars. Some have a lot of time and very little money. As we can see from the ancient world people delivered some of the most amazing artifacts with this technology. They also left us with biblical, hindu and ancient american myths of the Shamir, Siva disk and sun disk of Peru. respectively.

We are still trying to figure out who, why and how the pyramids and other colossal statues were carved. We have no real answers. Some say the pyramid stones were poured into forms yet we see stone blocks in various stages of being cut out of the quarries. Dolomite hammers made of harder stone is not the answer. Diamond saws maybe.

ReplyDelete